DRIVEN TO LEAD

BIM / ENGINEERING

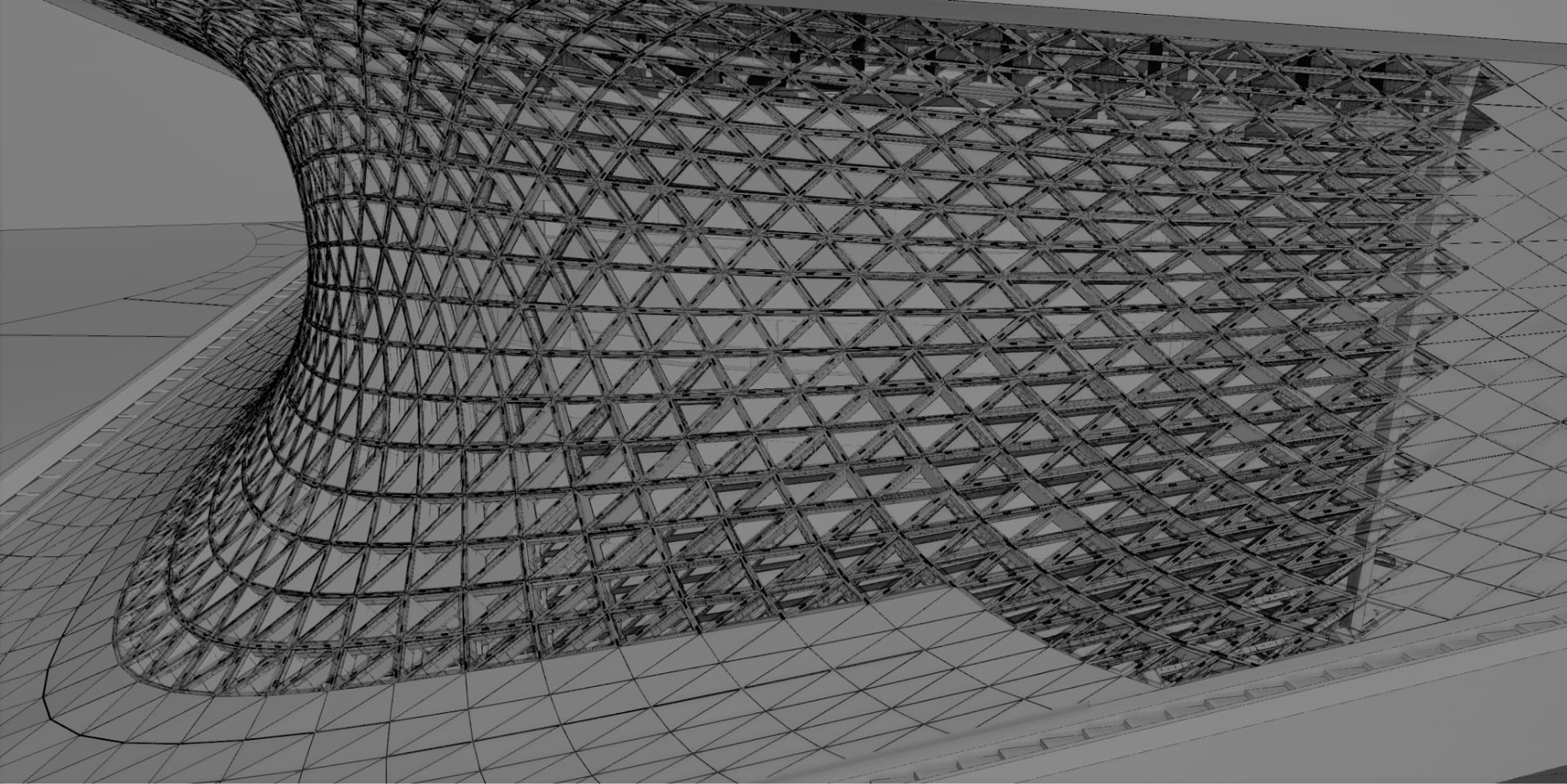

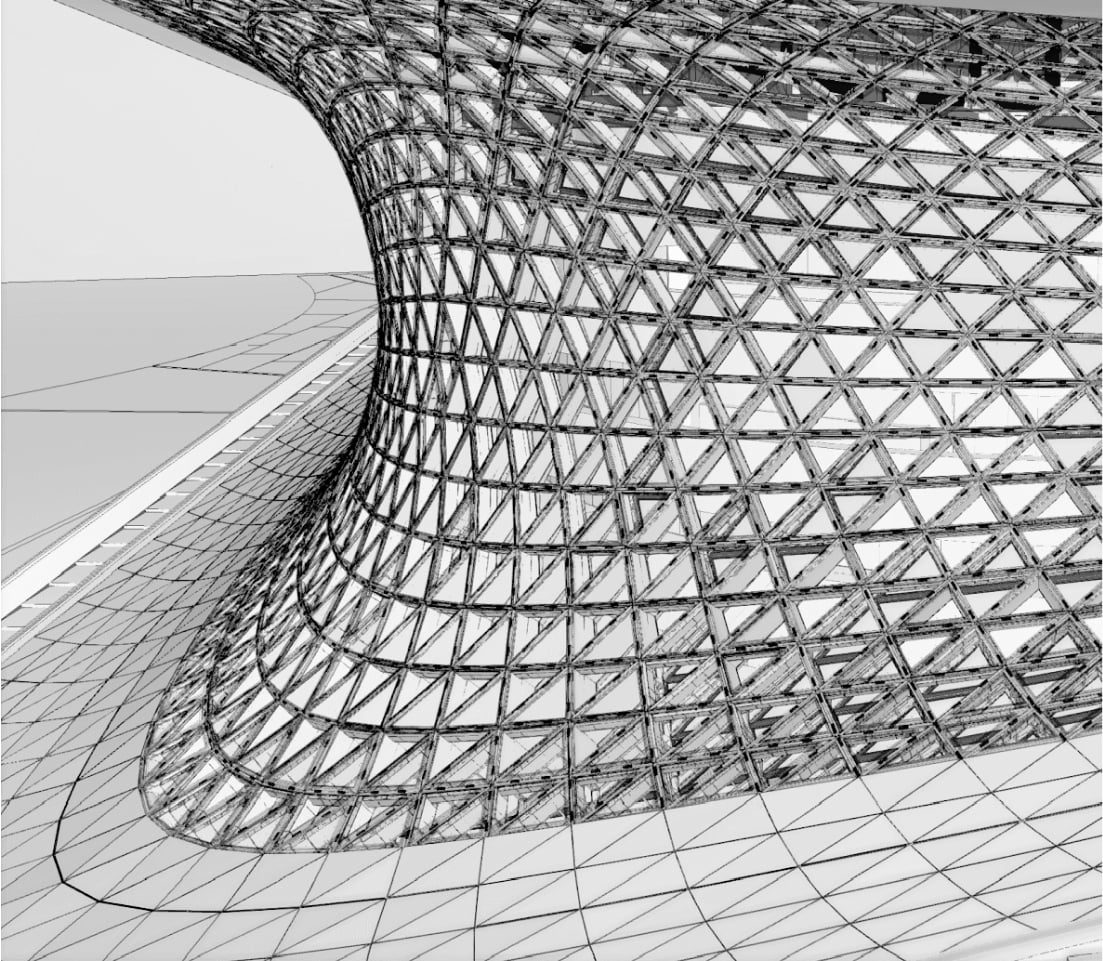

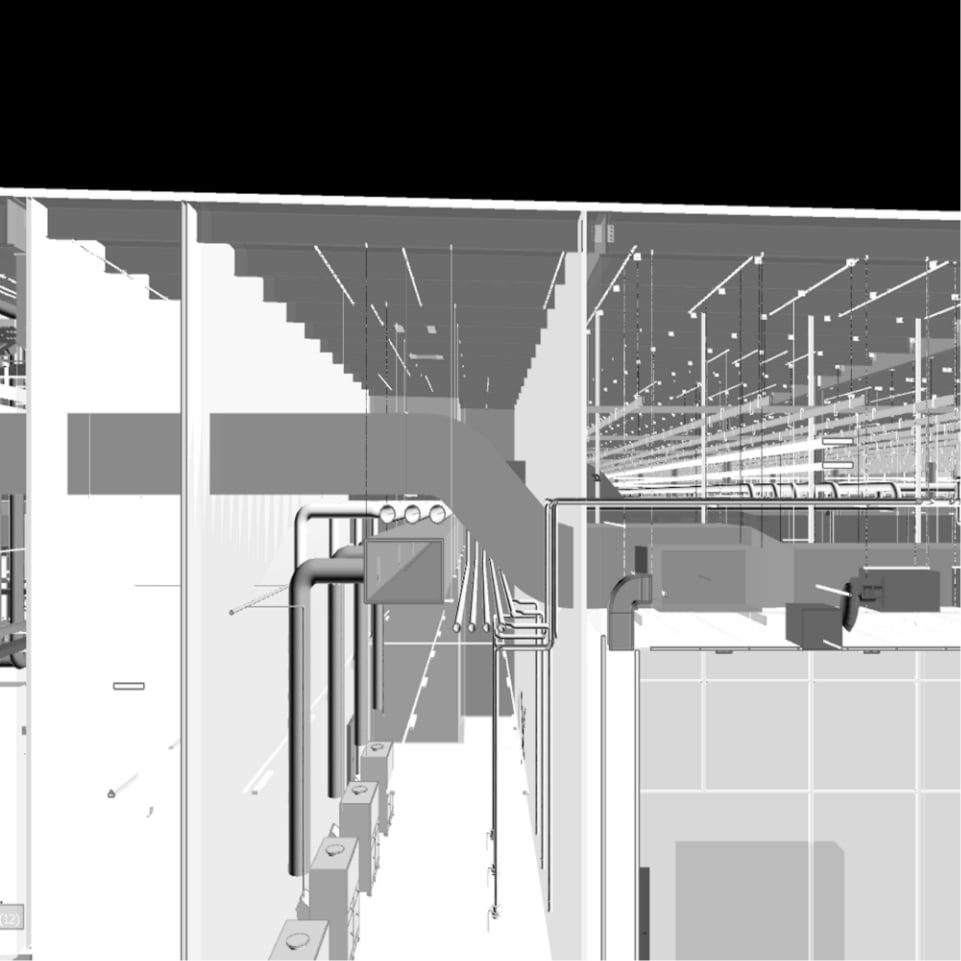

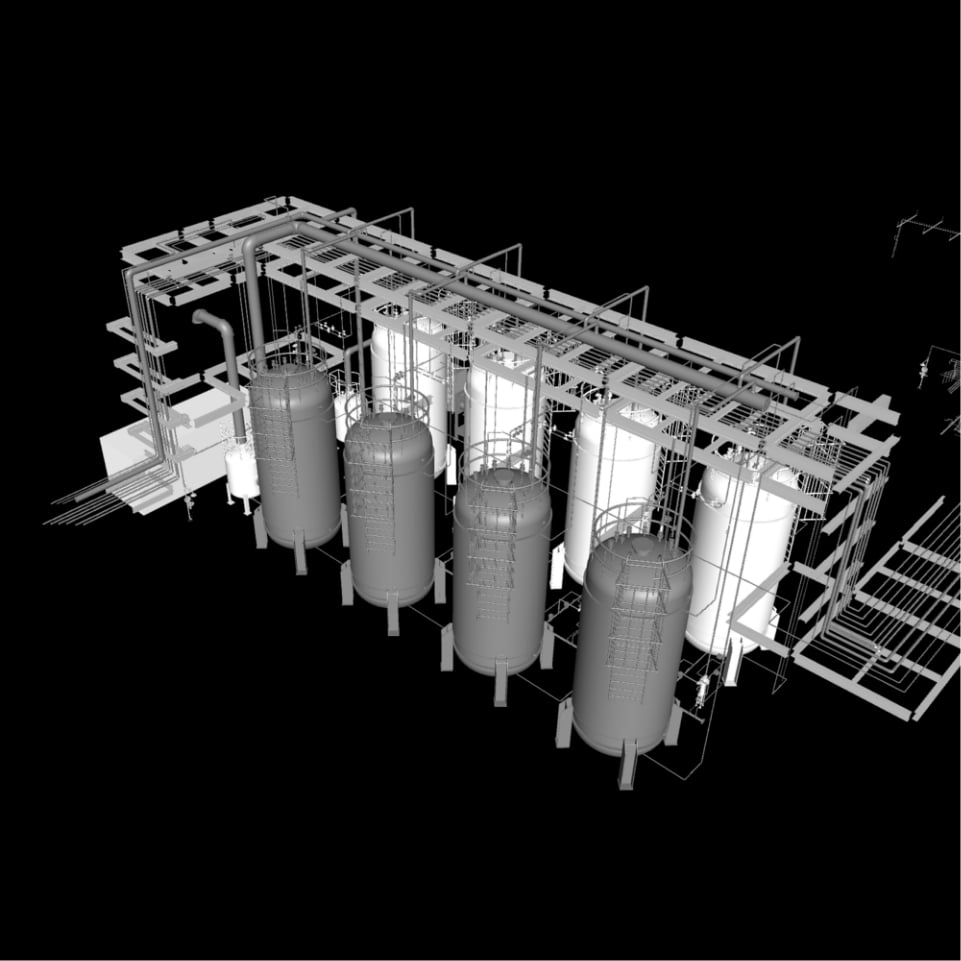

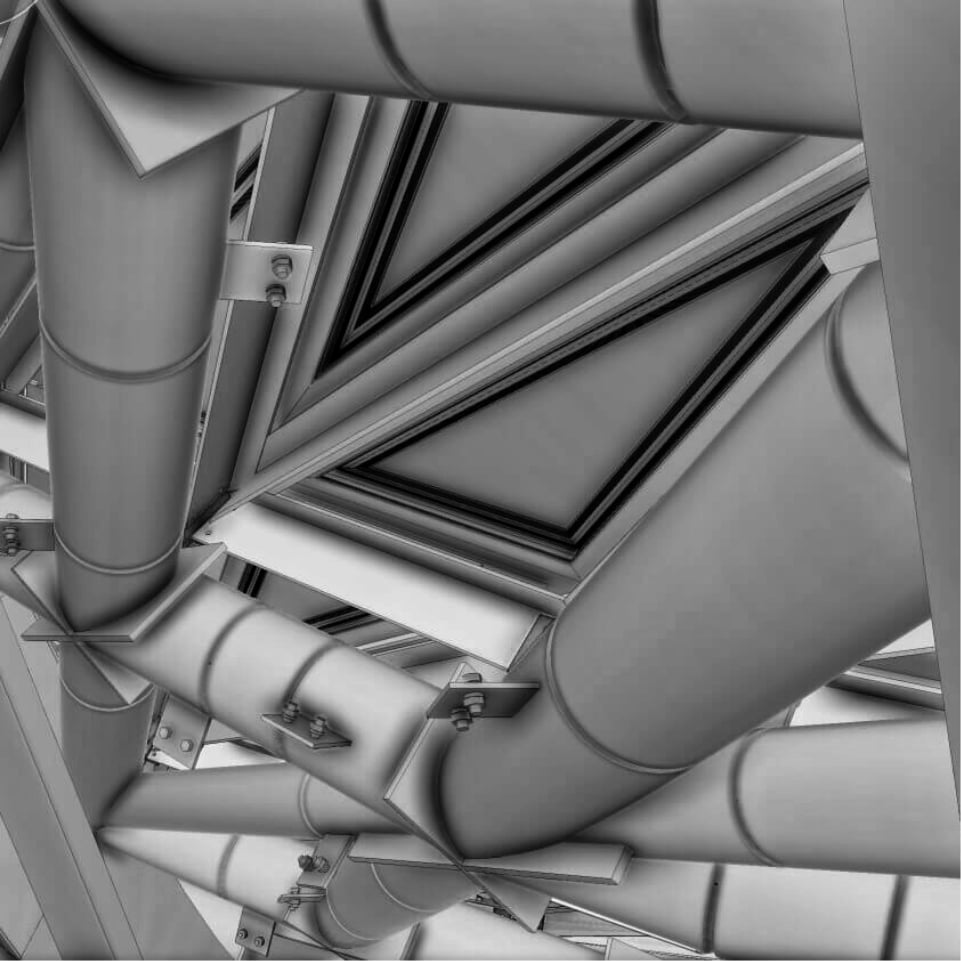

Procon E&C, Inc. utilizes advanced BIM technology to support precise engineering and manufacturing processes. Our modeling team creates fully coordinated 3D models driving to prefabrication. By integrating design and construction data, we minimize on-site conflicts, reduce material waste, and ensure seamless field installation — enabling efficient, high-quality delivery.

+ DIGITAL FABRICATION

JOINT VISUALIZATION

LASER CUTTING AND ENGRAVING

ON-SITE INTEGRATION

+ MECHANIC ENGINEERING

CLASH DETECTION AND COORDINATION

QUANTITY TAKEOFF

COST ESTIMATION

MECHANICAL SYSTEM MODELING

- HVAC Systems: ducts, AHUs, chillers, etc.

- Piping Systems: chilled water, condenser water, etc.

- Fire Protection Systems: sprinkler routing, valves, heads, etc.

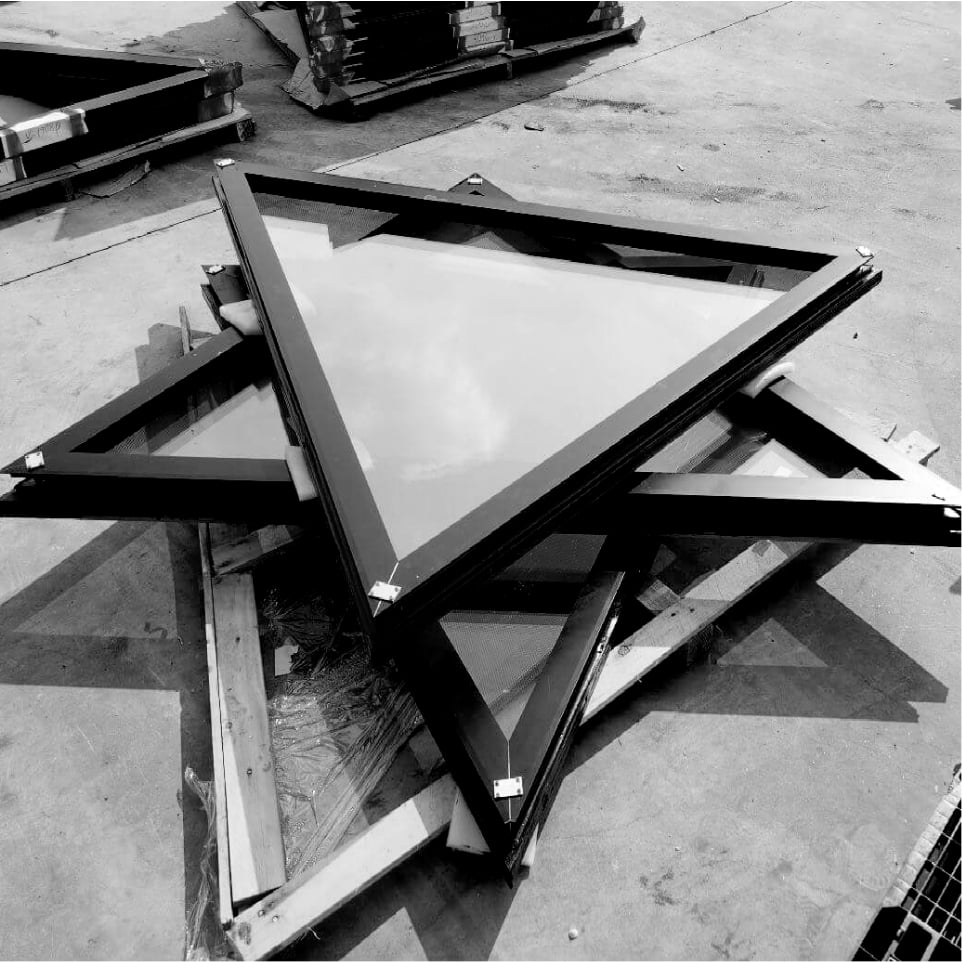

+ FACADE DESIGN

PARAMETRIC DESIGN

GENERATIVE DESIGN

PERFORMANCE ANALYSIS

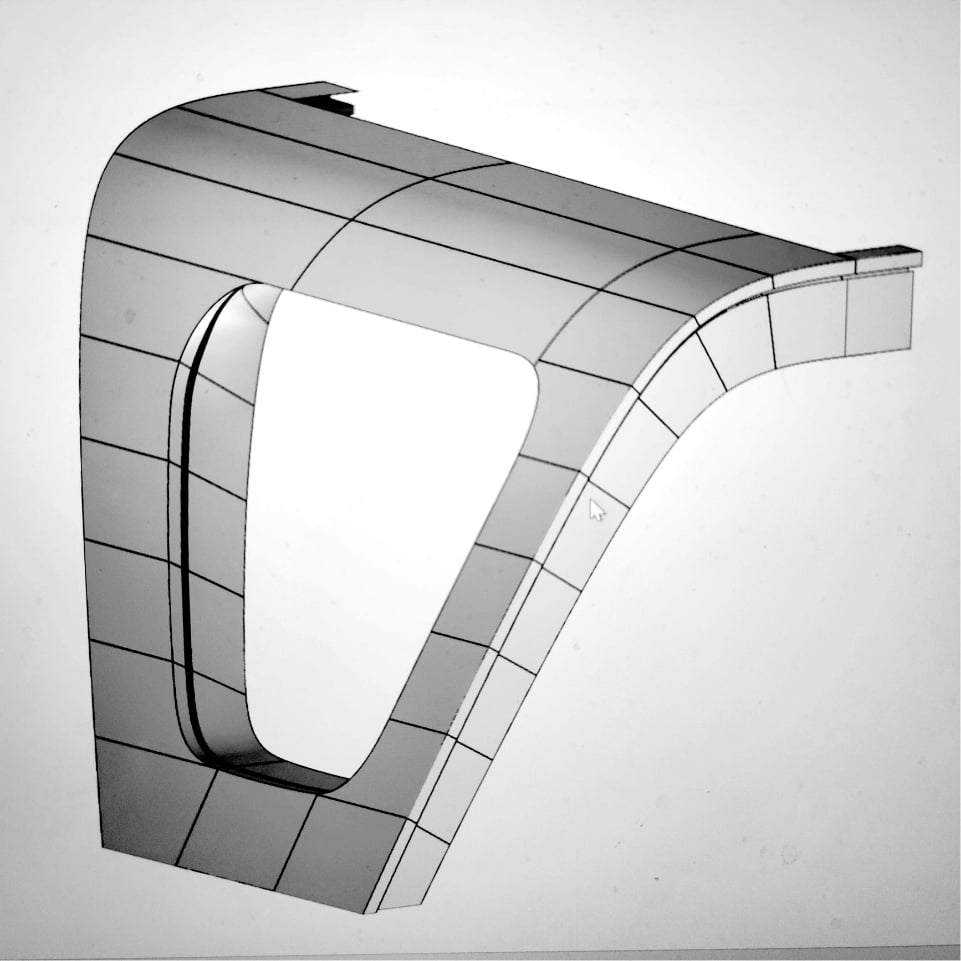

MOCKUPS AND PROTOTYPING

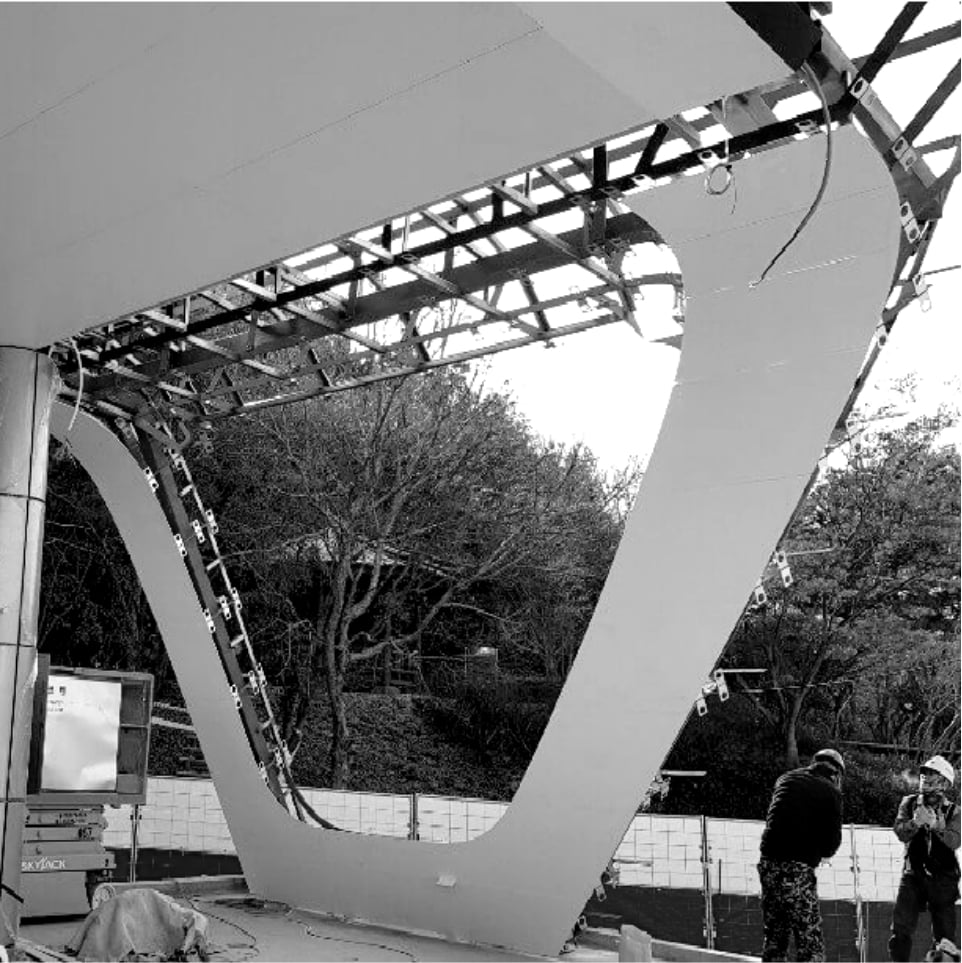

Code to Construction

Procon E&C, Inc. revolutionizes the construction through a digital-twin BIM platform, harnessing the Design for Manufacturing Assembly (DfMA) solution. Integrating architectural design with automation and manufacturing, we streamline the process from design to installation. This system thinking approach optimizes the productivity in cost, schedule, and risk management.

The complexity of façade systems, enabed by detailed modeling

In-house fabrication lab to streamline seamless production between design and practical construction.

The codified manufacturing libraries encompass structural framing and facade elements on site.

The codified manufacturing libraries encompass structural framing and facade elements on site.

Mapping intricate conduit systems with detailed clash detection, we pursue efficient field execution.

Clash detection through BIM allows us to identify and resolve conflicts between structural, architectural, and MEP systems before construction begins, reducing changes and delays.

The BIM model of built structure enables to optimize construction seqeunces, material estimation, and potential issue detection. It improves client specification under the situational condition.

The BIM model of built structure enables to optimize construction seqeunces, material estimation, and potential issue detection. It improves client specification under the situational condition.

Our advanced BIM capabilities allow us to precisely model challenging curved surfaces, irregular shapes, and complex panelization systems.

The connection between digital design and physical fabrication ensures that every facade element is produced from the design builder’s perspective.

The connection between digital design and physical fabrication ensures that every facade element is produced from the design builder’s perspective.

Flowing comprhensive approach, we don’t have conceptual separation between design building, manufacturing, and installer.